オートケミカル用品

TCL JIS LONG LIFE COOLANT

Engine antifreeze coolants

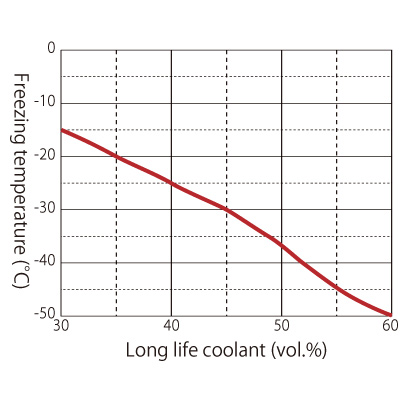

TCL long life coolant is an antifreeze coolant that conforms to class 2 of JIS K2234 (Engine antifreeze coolants). It provides long term freeze prevention properties as low as -50°C depending on the dilution rate.

The main component of the TCL long life coolant is ethylene glycol whose features is a high boiling point, so it almost never evaporate in undiluted solution.

Characteristics Table

| The Product kind | Engine antifreeze coolants |

|---|---|

| Brand name | Long Life Coolant |

| Standards | JIS (Japanese Industrial Standards) / Passed Class 2 |

| Type | Diluted type of non amine long-life coolants |

| Based glycol | Ethylene glycol |

| Recommended use concentration range | 30 vol.% ~ 60 vol. % |

| Freezing temperature range | -15°C ~ -50°C |

Product Specifications

| Volume | 2 L |

|---|---|

| Size of a piece | 11.5 x 11.5 x 26.5 cm |

| Size of a cargo box | 47 x 35 x 28 cm |

| Quantity | 12 pcs |

| Weight of a piece | 2.41 kg |

| Weight of a cargo box | 29.86 kg |

Outline

The coolant is used as a heat exchange medium in the cooling system. It is used to cool water cooled engines in the automotive industry. This blend prevents rusting of metals in the cooling system, overheating in summer and freezing in winter. It is named LLC (long life coolant) as the cooling liquid that can be used maintenance-free for long term.

TCL long life coolant is an antifreeze coolant that passed Class 2 of JIS K 2234 (Engine antifreeze coolants). It is a highperformance cooling agent to powerfully keep the corrosion resistance of internal of cooling system.

TCL Long Life Coolant has excellent anti-corrosion effect by the addition of high-performance anti-corrosion agent. To prevent overheating in summer, and freezing in winter, it can withstand long-term harsh conditions throughout the year.

Characteristic

High-performance antifreeze coolants

TCL long life coolant is an antifreeze coolant that has passed class 2 of JIS K 2234 (Engine antifreeze coolants). It is a coolant that has long term freeze prevention properties of up to -50°C depending on coolant and water dilution rate. Long Term anti rust and ant corrosion properties can be used in the long term as it does not produce any solid precipitate and also does not cause swelling and softening of rubber.

Higher boiling point

Glycol that has a boiling point of close to 200, with no evaporation in concentrate form and low evaporation rates when mixed with water.

Using a high-boiling materials as main components

The main component of TCL long life coolant is ethylene glycol having a boiling point close to 200°C, so it almost never evaporate in the case of undiluted solution. In addition, because it has a boiling point of 100°C or higher, even when mixed with water, and rarely evaporates during use.

How to use

- Discharge the old coolant in the cooling system completely, and flush the inside of it well.

- Inspect the cooling system inside, please repair if there is a point of leakage.

- Check the amount of cooling fluid and the lowest temperature of your area. Decide the dilution ratio with dilution rate table and calculate amount of undiluted solution. Pour in the correct amount of it, and pour in soft water (tap water) until 2 ~ 3 cm below radiator cap’s bottom.

Long life coolant dilution rate table

| Freezing temperature (°C) | -15.2 | -18.9 | -24.0 | -29.6 | -35.5 | -42.5 | -50.5 |

|---|---|---|---|---|---|---|---|

| Long life coolant (vol.%) | 30 | 35 | 40 | 45 | 50 | 55 | 60 |

| Tap water (vol.%) | 70 | 65 | 60 | 55 | 50 | 45 | 40 |

Precaution for using

- TCL Long life coolant has the long-term durability of continuous use for two years. Regularly check the liquid volume, and supplement with TCL long life coolant when the liquid is reduced, please keep always the initial concentration.

- For corrosion prevention, please use at concentrations of up to 30-60% by volume.

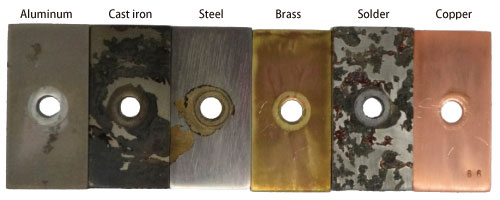

The role of anti-corrosion performance

Our products - New coolant

Case of coolant which has low anti-corrosion quality

There are lots of corrosion on manu of the test pieces which can cause overheating due to corrosion clogging, leakage etc of the radiator.

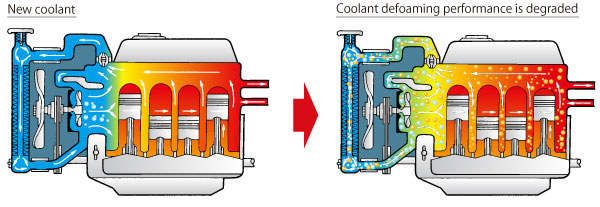

The role of anti-foaming performance

Degraded coolant loses antifoaming performance and foam will obstruct coolant circulation in the cooling system. The radiator will not cool the engine effective and will cause overheating. In addition, it will increase the risk of radiator damage due to cavitation.

Degraded coolant loses antifoaming performance and foam will obstruct coolant circulation in the cooling system. The radiator will not cool the engine effective and will cause overheating. In addition, it will increase the risk of radiator damage due to cavitation.

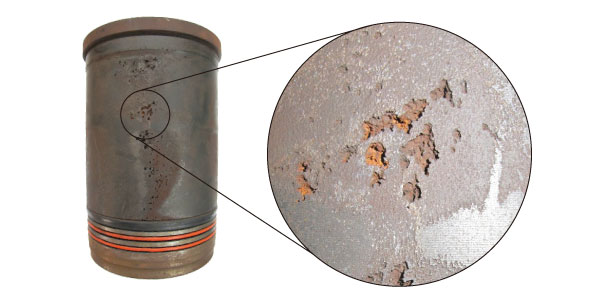

Foam causes cavitation

which corrodes the cylinder liner.

It is a corroded cylinder liner by cavitation which is caused to degraded coolant.

Cavitation is the phenomenon that bubbles are generated and disappeared. It will cause pressure changes due to poor circulation and vibration of coolant. The shock of ruptured bubbles causes high pressure in the system and will damage the cylinder liner and water pump.

Cavitation is the phenomenon that bubbles are generated and disappeared. It will cause pressure changes due to poor circulation and vibration of coolant. The shock of ruptured bubbles causes high pressure in the system and will damage the cylinder liner and water pump.

Deterioration of the coolant can not be

judged only by color !

We recommend regular LLC exchange

in order to prevent the trouble !